Spotlight on RHINOFAB1350

Built for Shops That Can't (or Won't) Automate.

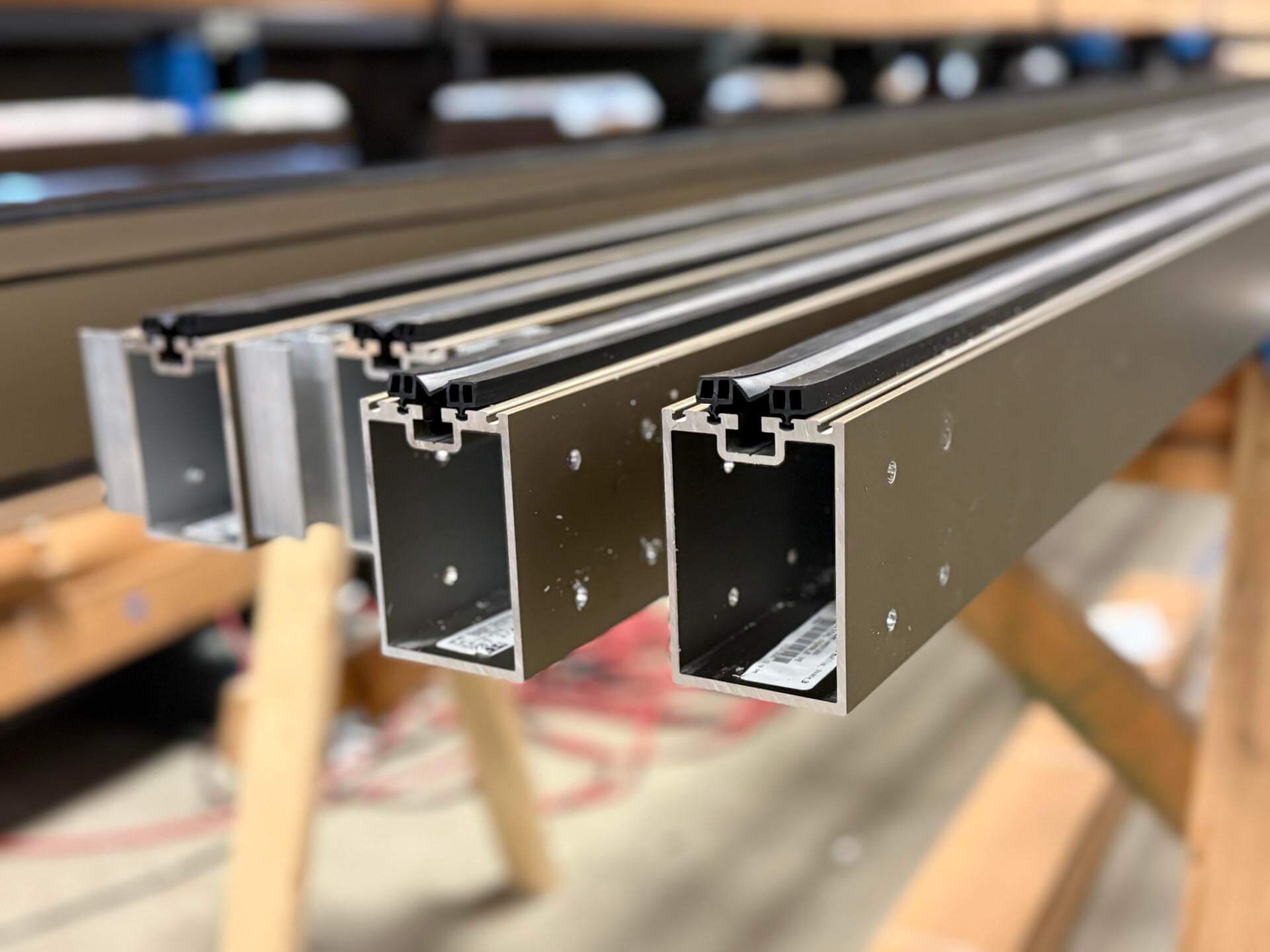

The RHINOFAB 1350 is the heart of our operation — a CNC machining center designed to handle the precision and speed most shops can't achieve on their own. By automating complex cuts, routs, and hardware preps, it removes the bottlenecks that slow projects down. For contractors, that means fewer errors, faster turnaround, and a predictable flow of field-ready components without the burden of owning or maintaining the technology.

In-House Fab vs. Pinnacle

See how Pinnacle stacks up against traditional shop work.

In-House Fabrication

- Labor-Heavy: Skilled techs tied up on repetitive cuts and routs.

- High Overhead: Machines, shop space, and ongoing maintenance costs.

- Inconsistent Output: Errors mean rework, wasted material, and lost time.

- Limited Capacity: Only as fast as the people and machines you already have.

Outsourced with

- Labor-Free: We handle repetitive fabrication so your techs stay focused on installs.

- Zero Overhead: No investment in equipment, upkeep, or extra shop space.

- CNC Precision: Clean, repeatable results that eliminate costly rework.

- Instant Scalability: Expand capacity on demand without adding staff or shifts.

Why Automation Matters?

Reduce rework, speed up installs, win more profitable jobs.

Experience the Automation Advantage

See how our RHINOFAB 1350 can transform your fabrication workflow.